Add Your Heading Text Here

Lorem ipsum dolor sat amet,consectetur adipiscing elit。 Ut elittellus,luctus nec ullamcorper mattis,pulvinar dapibus leo。

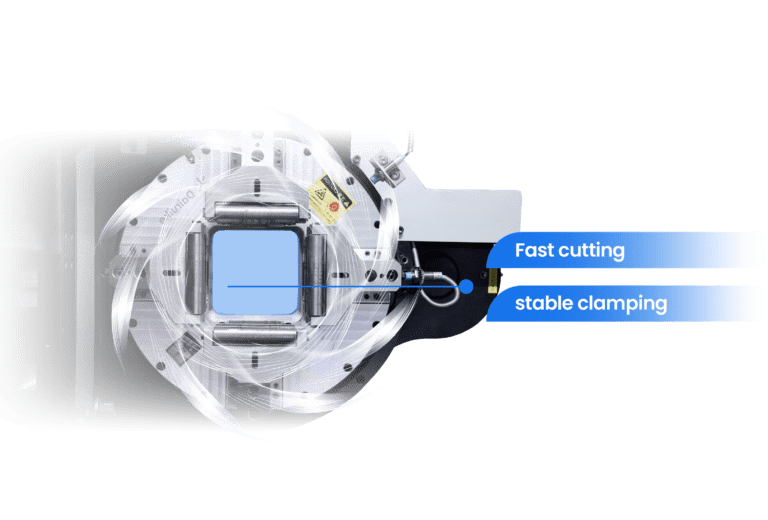

Full stroke precision square hole chuck

K series’ precision chucks are well-suited for the rapid cutting in dynamic applications and stable clamp without damaging the workpiece.

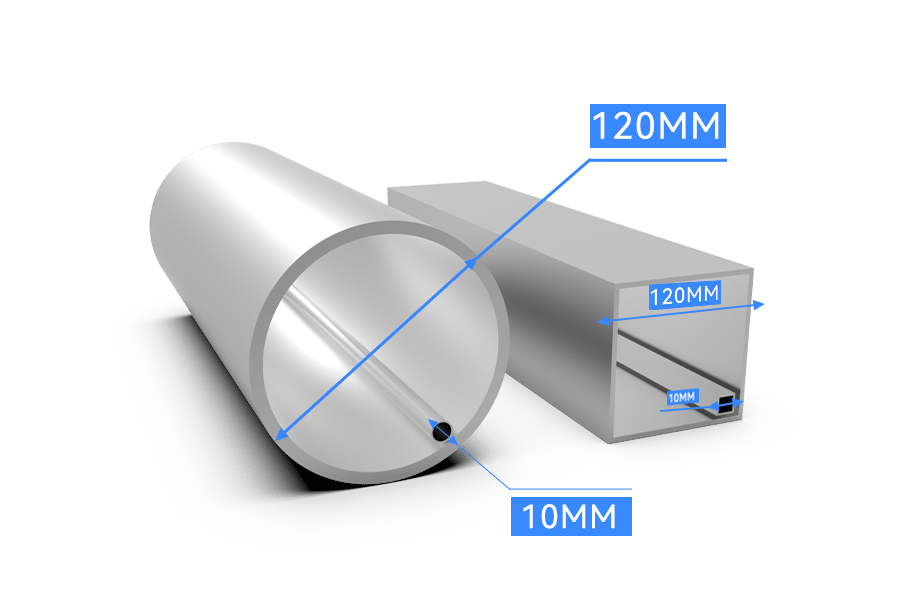

Wide Range of Tube Cutting

K series machines used for cutting round tubes, square tubes, channel beams, angle beams, etc.They provide smooth cutting of tubes ranging from 10 to 120mm in diameter.

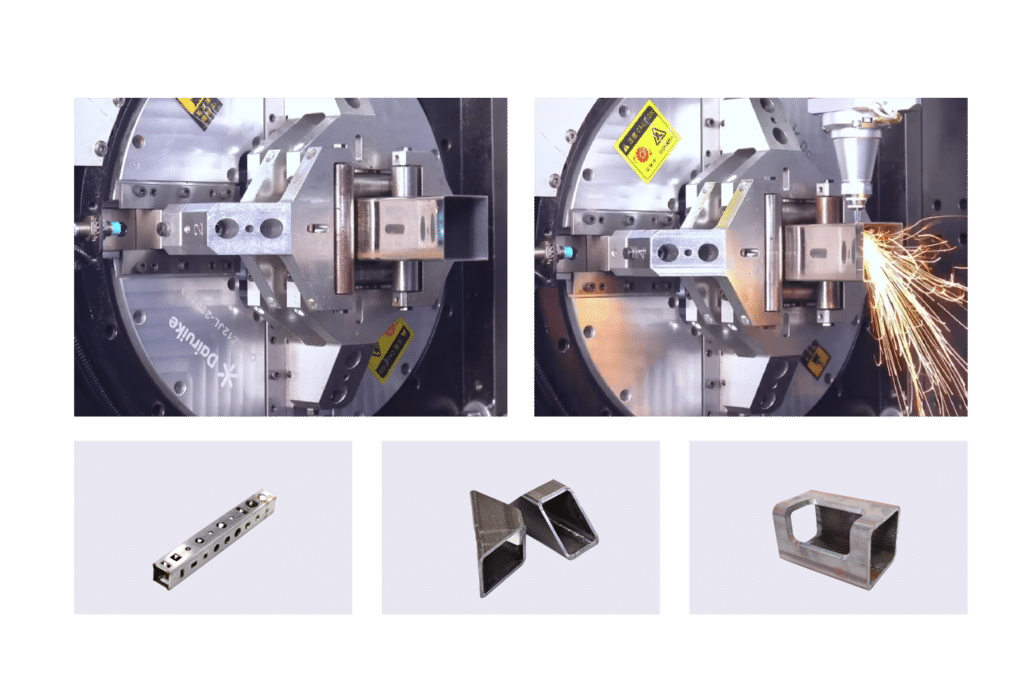

Diversified Tube Processing

The multifunctional integrated solution offers high efficiency in cutting, punching, and grooving—one machine handles multiple tube processing tasks.

±45° bevel cutting(*Optional)

Optional bevel cutting capability can be equipped with bevel cuts from -45° to +45°. Depending on the part geometry, simple V- and X-seams can be cut, as well as more complex V- or K-seams.

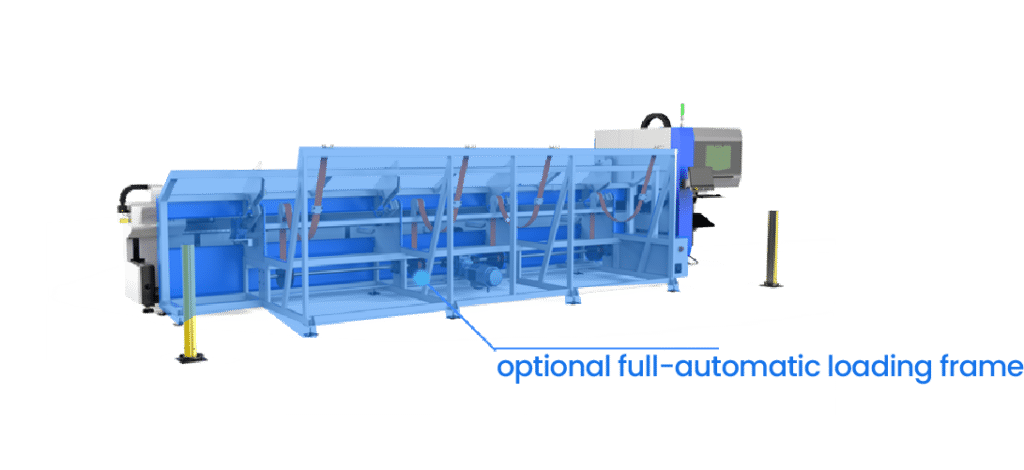

Semi automatic loading system

The optional fully automatic loading frame for batch feeding can free up labor resources, save time and labor costs, and double the processing efficiency.

What is the price of laser cutting and engraving machine?

Laser cutting and engravi

Why is fiber laser cutting machine more and more popular?

Fiber laser cutting machi

What are the application of fiber laser cutting machines?

Fiber laser cutting machi

Ultrahigh-power Laser Cutting Continues Growth Path

Ultrahigh-power laser cut

How to use and maintain a fiber laser cutting machine?

Fiber laser cutting machi